HOME TECHNOLOGIES NEWS PRODUCTS

Broad versatility

The exceptional and vast visual plasticity of wood is an additional benefit, enabling the material to be connected with practically any brand story, in addition to the sustainability advantages it offers.

Wood can not only have a natural & rough look, but also offer your goods with a refined, soft, and sumptuous personality thanks to our sector-leading decoration facilities.

Discover below how unlimited color, shape, and design options change what wood can be for your beauty business..

Shapes®

Almost any shape that a client requests can be obtained from us! The factory contains two components for this purpose:

The turned wood department

Circular geometric shapes are made feasible by turners, a “shaping” instrument. The fundamental procedures utilized by the artisanal turners of antiquity are replicated in this industrial technique. The modern procedure is different in that it is an industrial process that is completed automatically by robots and machines.

The carved wood department

Molding machines or CNC routing machines are used to produce complex forms and asymmetrical geometries. The latter can define and shape a variety of surfaces thanks to its three interpolated axes. These machines’ cutting-edge software can generate an unlimited variety of unique geometric designs.

Finishes

Stains and lacquers

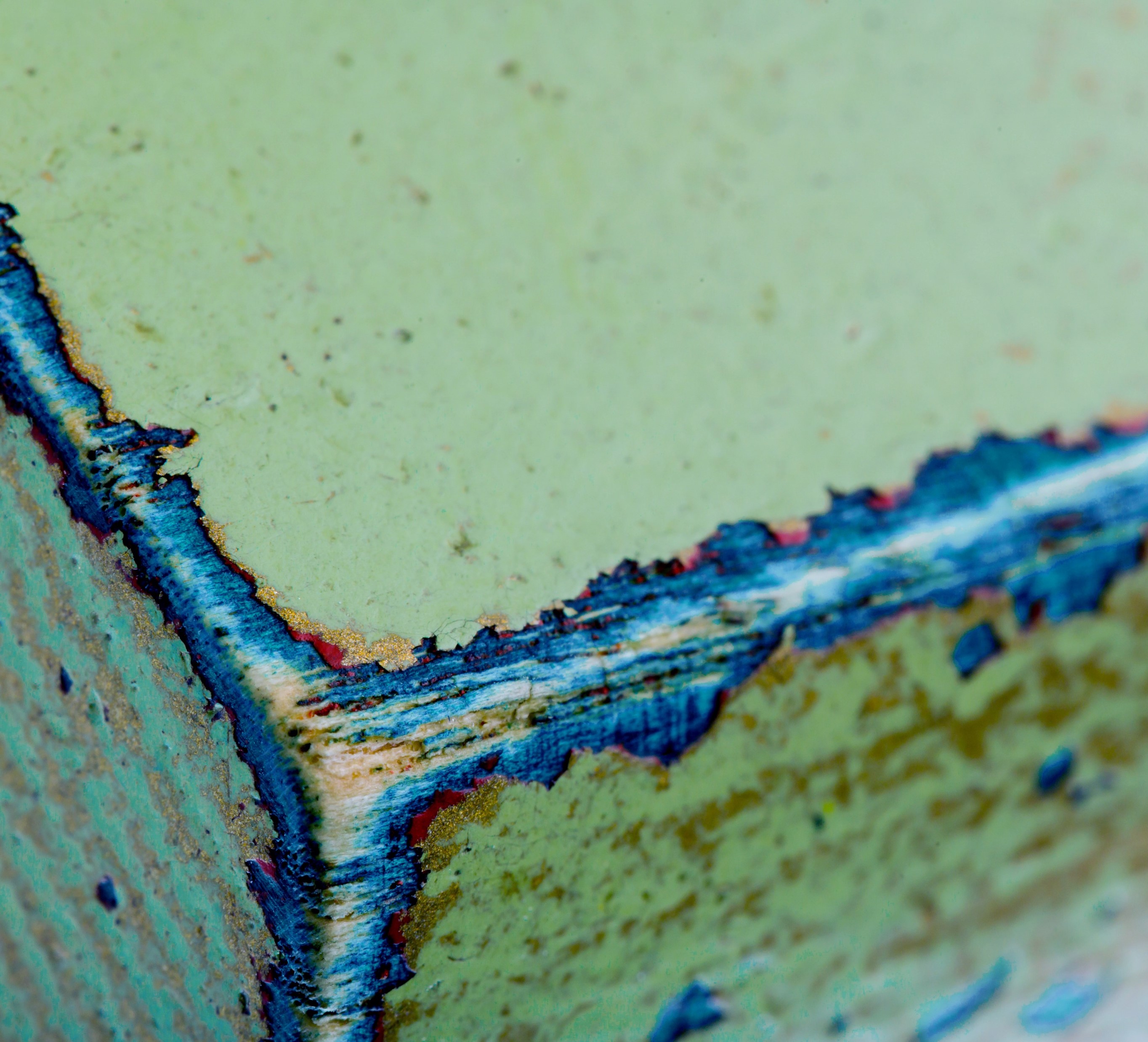

Stains and lacquers are the two coloring methods that can be used on wood.

Stains can be used to create a wide range of colors because they are transparent coatings. This shade might more or less clearly show the wood grain depending on the color.

Lacquers are absolutely opaque and completely conceal the wood’s grain. Similar to how they are used with plastic or aluminum, these lacquers come in a wide variety of colors and offer a consistent surface.

Varnish

Varnish gives the piece a clear covering that protects it. It serves as defense against UV radiation, dampness, and other environmental elements. Additionally, varnish has the advantage of filling the pores of the wood and preventing any potential dimensional alterations..

Top coat

This is applied on the last layer of varnish and can be adapted to the requirements of the end product. Normally, the top coat is used to affect the brightness of the end product. The top coat can create a large range of finishes, all the way from a dull, light-absorbing matte to a an incredibly brilliant, high-gloss shine.

Decoration

Wooden parts look fantastic when they are left in their original state. However, when combined with our variety of decorating options, wood becomes something revolutionary and disruptive.

Our methods, which include silkscreen printing, laser etching, hot stamping, and pad printing, each provide another level of visual innovation and customization.

There are also further, more unusual techniques available, such as wood charring, gold leaf, layering, and micro-engraving. You can see some of these strategies in action by scrolling through the slideshow on the right.